Is robotic welding the future of industry? See what a welding robot can do.

05.10.2021

Automation of industrial processes has been going on for many decades. More and more work in factories is performed by robots instead of people. Decades ago, this was only possible for simple and repetitive activities, but the development of technology allows us to perform increasingly complex tasks. An example would be welding of details. What jobs can welding robots perform today and will they soon replace people in factories? Read!

Welding is a difficult art

This profession requires not only appropriate knowledge and skills, but also talent and intuition. Which is why good welders are highly valued. However, even the best specialist will not make two identical welds. This is due to a multitude of factors and nuances that determine the final effect of his work. How can robots help in this aspect?

Their work is more repeatable, but the robot can only execute the program given to it. This means that an experienced employee will be needed to set the appropriate process parameters - but he or she only needs to set them once. Then a pre-trained employee can, with assistance welding robot, perform operations on subsequent details. That's why automating the welding process is so tempting.

Benefits of robotic welding

Implementation welding robot in the production process seems to be quite an expensive process. Basic costs include:

- Purchasing a suitable stand.

- Implementation of technological programs and their testing.

- Training operators to use the welding station.

However, these expenses bring clear benefits and they determine the sense of such an investment. It is therefore worth familiarizing yourself with them carefully.

Safety when welding with a welding robot

Safety at work is the most important thing. The welding process is not very health-friendly. High temperature and bright light can damage your eyesight after many years of continuous welding, and additionally, the process releases harmful compounds which, although in small quantities, may have negative health effects in the long run. Robot welding allows you to separate the operator from welding station, making his work becomes much safer.

Significant increase in efficiency thanks to welding with welding robots

Welding with a welding robot increases the efficiency of the entire process. Unlike humans, the machine's movements are extremely precise and fast. They can quickly create a weld that even a good welder would have to work on for a long time. Additionally, the robot can easily work 24 hours a day, seven days a week without feeling tired. Thanks to this, you can often see a huge increase in the number of details made on a given item welding station in one day. The consequence of this may be a reduction in the number of positions or an increase in production.

No problems with acquiring the best welders

A good welder is expensive, and the current situation on the labor market makes it difficult to find one. Experience, skills and, above all, talent for welding are highly sought after skills. Welding with a welding robot solves this problem. All you need is one talented technologist who will implement the programs for everyone welding stations. Service themselves welding robots may be handled by less qualified workers.

High welding repeatability welding purposes

Main advantage welding with welding robots is repeatability. Their precision allows you to precisely recreate the process and obtain virtually identical results. Thanks to this, the highest quality weld is produced every time, which also minimizes the need for further processing of the joints. This translates into further savings in costs and production time.

The flexibility of robot welding

It may seem that robotic welding it only facilitates the work of large production halls where the same details are produced all the time. However, retooling welding cell it's not that time-consuming at all. Most often, it is enough to switch the program and possibly replace the equipment with appropriate ones included in the technological card of a given detail. That means now Within a few minutes, the welding robot is ready to work on another detail than before.

The prestige of a company using modern welding robots

Using modern solutions increases the company's prestige. Employees will appreciate it wanting to work for a rapidly growing manufacturer. This will be an opportunity for them to develop quickly. On the other hand, customers will also be more willing to use the services of a company that uses modern technologies welding robots. They will count (and rightly so!) on higher quality of the products they receive and shorter production time.

The best robot welding solutions

Depending on your needs, you can use universal ones welding cells guaranteeing great repeatability of the welding process. They are intended for simple details. An alternative is more advanced, dedicated stations with welding robots that can cope with more difficult tasks.

Welding purposes and its advantages

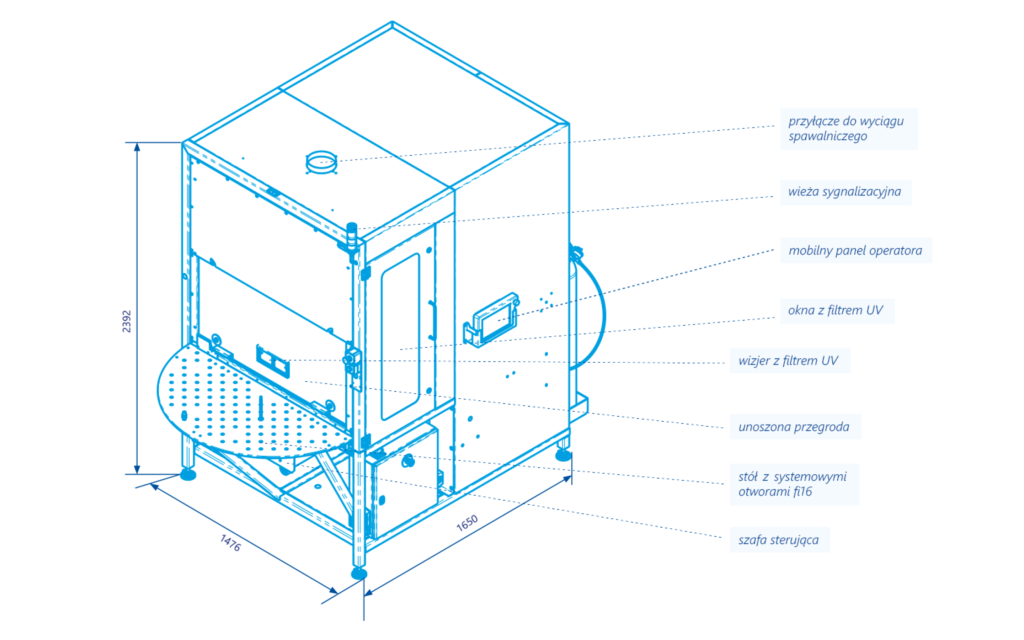

In order to robot welding You can equip yourself with various devices, however welding cell stands out in a special way from other solutions. It is a small, tightly closed position, which is important in terms of safety. Inside there is a rotating table with standardized holes for mounting the equipment in which the welded detail is mounted. What are the benefits of such a solution?

- Increase work safety and ergonomics.

- Small space, which is needed for the operation of the station.

- Possibility of moving the cell into various production areas.

- Possibility of welding methods MIG, MAG and TIG (depending on the selected equipment).

- Increasing the production rate, thanks to precision welding robot.

- Lower employee costs.

- Very high quality and repeatability of welds.

- Easy programming and conversion to other details.

- Low implementation costs.

Robot for special tasks

In the case of more complex production processes, investors can opt for a multi-robot and fully automated welding station with a parts warehouse and a robot that transfers the detail between subsequent stages of the process. The robot can be equipped with auxiliary systems that further improve the entire process. If it is not possible to position the detail repeatedly or it may be deformed during welding, the welding robot can be expanded with functions such as searching or tracking welds.

· Search for joints is useful for elements with unfriendly geometry. Using this function, the robot finds the target location of the weld, thanks to which it positions itself appropriately in relation to the detail. This enables precise welding of details that are difficult to clearly attach to the device.

· Weld tracking, In this case welding robot will track the welds being created and record the resulting material deformations. Thanks to this, the process will automatically adapt to changes occurring in the detail, which will increase the precision and quality of the weld.

The use of such systems allows you to achieve the highest quality, also when welding unique and individual elements.

Will robots replace welders in the future?

Welding robots produce details of high quality. They also produce repeatable elements that do not require subsequent finishing. In the production process, it is not possible to robotize each of the welding stages. Even though more and more companies decide to automate this process, experienced and good welders are always in demand. They are needed to control, supervise and perform more difficult, small-series welds.

Author: Łukasz Tyczyński