Robotized bottle palletizing line at CANPOL

Canpol is the leader of the Polish market of baby accessories. For 30 years, it has been meeting the needs of children and their parents in over 50 countries, providing a full range of products in the field of feeding, care and care. The Canpol company and the Canpol babies brand have been awarded for years by prestigious institutions and monthly magazines for parents in Poland.

Canpol Sp. z o. o

Puławska 430

02-884 Warsaw

https://canpolbabies.com/pl_PL

DESCRIPTION OF THE CUSTOMER'S SITUATION

One of the reasons for the planned change was the desire to develop and introduce modern technologies and improve the current work model on the production line.

The client wanted to automate the packaging and palletizing process after the bottles were formed by the injection blow molding machine before delivering them to the pad printing machine where the print is applied.

Before the changes were introduced, operators were obliged to be constantly present on the production line and manually pack bottles into cartons, which they then moved to the next stage of production many times during the day.

SOLUTION

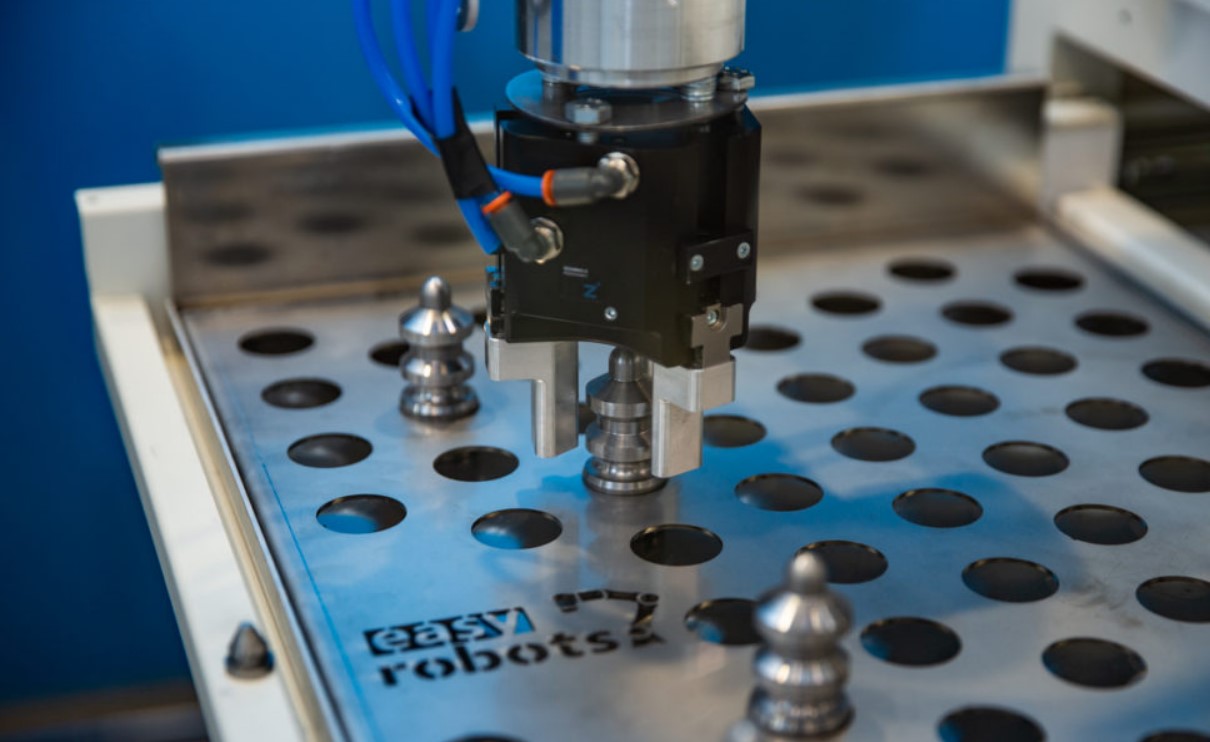

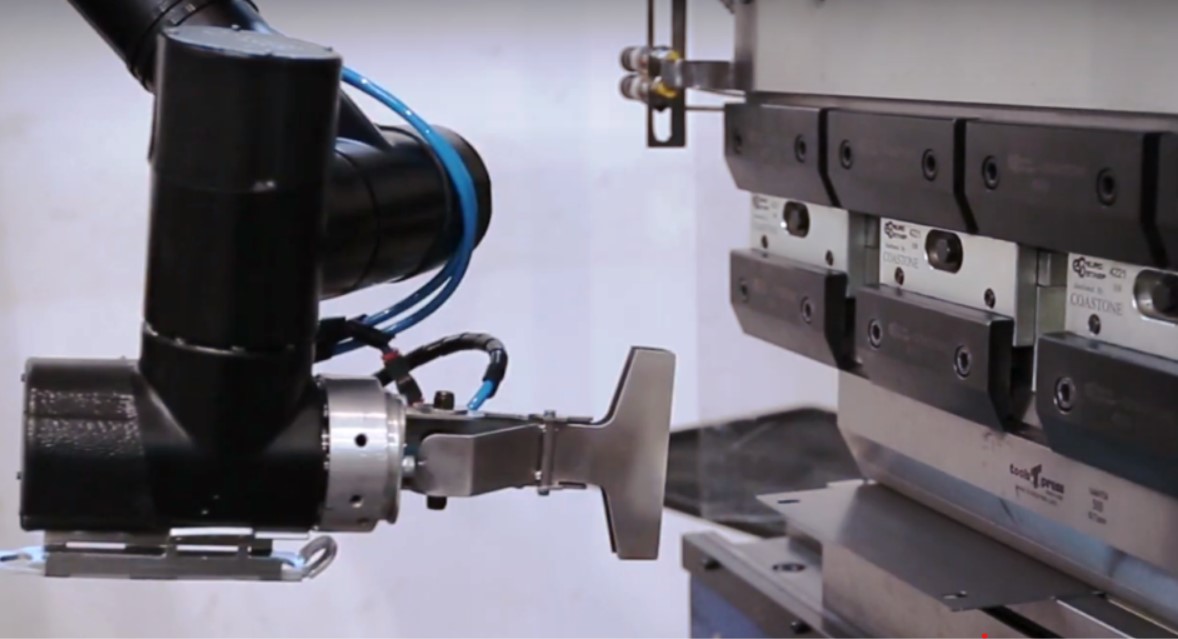

We used a palletizing line with a set of modular vaccum and roller conveyors, an additional vertical axis for the robot and an ES5 arm with a set of dedicated pneumatic grippers. As a result, we ensured efficient multi-layer stacking of bottles on a pallet.

Palletizing robots – the most important advantages

Automation of palletizing processes offers numerous advantages for the company - regardless of the industry field it specializes in and what materials are palletized or packed. The most important advantages of palletizing robots include:

– universality of use – in various industries and when packing/palletizing various goods, including cartons, bottles, jars, containers, cans and many others;

– possibility of programming any sequences according to which the robot performs subsequent activities, which ensures adaptation to the individual specificity of the process;

– precision, repeatability of movements and no downtime;

– significant increase in process efficiency and relief of employees from tedious, monotonous work;

– ease and safety of operation, as well as support from specialists in the implementation of robots;

– reducing the costs of palletizing and packaging, and therefore – the entire production.a.

If you are curious about how robots can help with palletizing in practice, please see the case study from Canpol. The full case description can be found here: https://easyrobots.pl/zrobotyzowana-linia-do-paletyzacji-butelek-w-firmie-canpol/.