Robotised welding

Explore the EASY CELL small and medium welding station

EASY CELL welding cells are available in two variants, differing in the size of the work areas. The first one is equipped with ES5 robot allowing a range of up to 92 cm. This option is perfect for multi-series production of smaller-sized products. For welding larger products, the second variant equipped with the ES8, which reaches a range of up to 127 cm and is suitable for large-scale production of small and medium-sized parts.

Complete tooling production

Instrumentation for robot welding is significantly different from those used in manual production, which is why as a company we deal with the production and final assembly of welding equipment. At the design stage, it is worth ensuring that the construction assumptions are correctly implemented. During robotic welding, the welding device is directly involved in the process. Therefore, together with experienced engineers involved in programming and process optimization, we create a device design that will guarantee the correct settings of the welded elements, optimize the cycle and the ergonomics of the operator's work.

More information about our welding stations can be found in the folder!

| Welding cell EASY CELL S | Welding cell EASY CELL M |

|

|---|---|---|

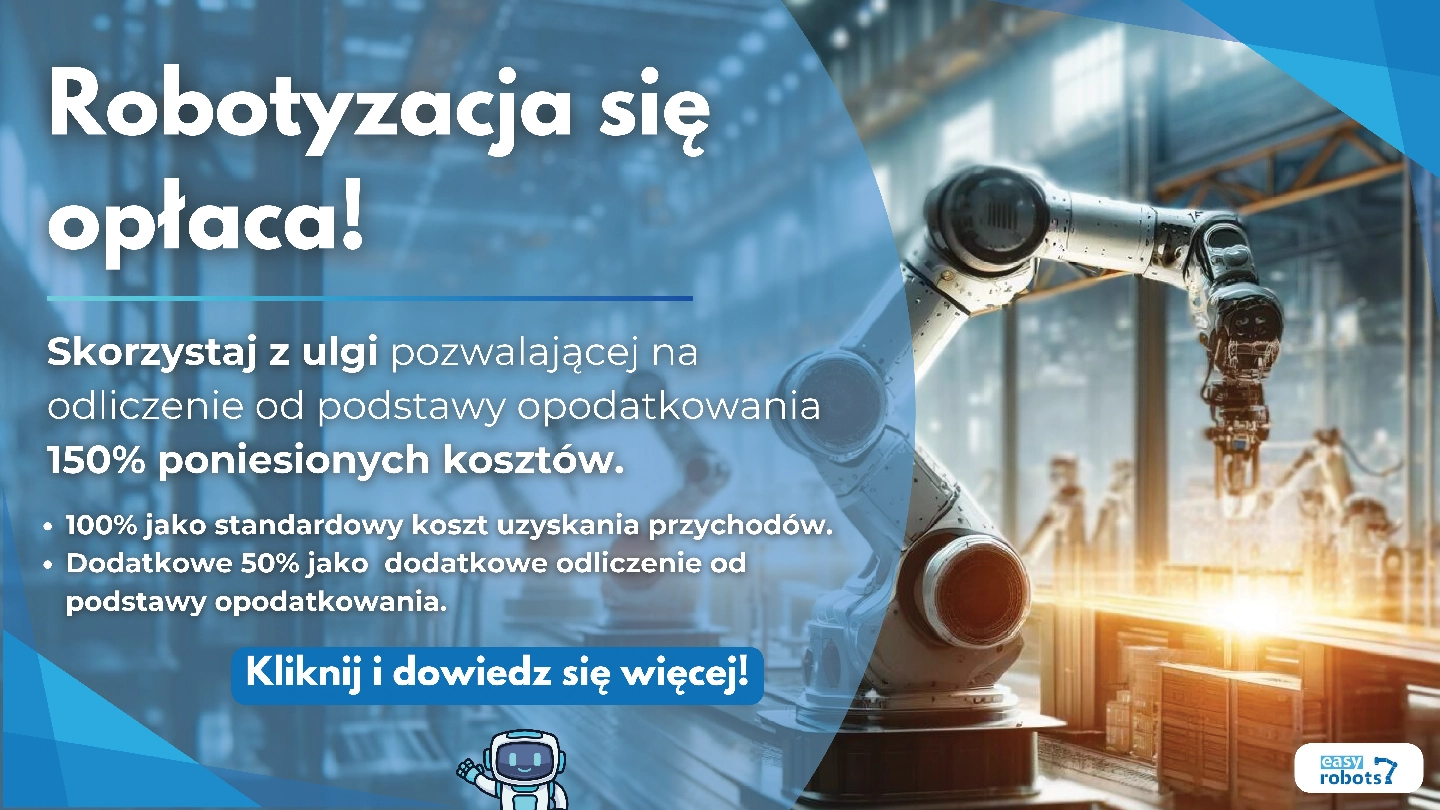

Robotised welding

Welding is an activity that requires experience, the ability to use modern equipment and great concentration. It can be tedious, burdensome and exhausting, and often takes place in conditions that are harmful to health. Therefore, there is a shortage of specialists on the market who would provide high-quality services in this area.

Fortunately, the development of technology makes it possible to fill this gap - the alternative is robotic welding , which for the company means lower employment costs, higher efficiency and repeatable quality of welds.

Robot welding or manual welding?

There can only be one answer - robot welding. Performing tasks manually poses numerous problems in this respect.

Manual welding involves:

Lack of repeatability |

|

even the best welder cannot reproducibly produce perfect welding results on every workpiece, and errors can creep in, causing downtime and wasted material.

Low performance |

|

a human will always work slower than a properly programmed, state-of-the-art robot and will need breaks, sick leave or holidays (as opposed to a robot that is always on standby)

Lack of specialists |

|

there is a growing shortage of experienced welders on the market, not only because it is a demanding profession, but also because of the decline in the number of active welders

Welding robot – efficient support for your company

Production automation is the best way to develop your company. One of its elements may be robotization of the welding process, which, thanks to the highest precision, repeatability and efficiency, will shorten the entire process and ensure a much higher quality of products. At Easy Robots, we provide our clients with technologically advanced welding robots that can be freely programmed and thus adapted to specific needs and the objects being welded.

A properly configured device will perform welds precisely, maintaining the appropriate speed and following the designated path. Without any downtime, no risk of material loss or reduction in production quality. Moreover, robotic welding enables the use of various techniques and methods, such as MIG, TIG, arc or spot welding. Thanks to this, it works well in every field of industry and can support all enterprises - regardless of the type of welded objects or working conditions.

What can be welded with a robot?

Machine parts and steel furniture elements, components in many areas of production and many other elements. As a result, the welding robot will work well in the furniture industry, electronics industry, automotive industry, metal processing plants and many other enterprises.

The most important advantages of robotic welding are:

- excellent joint quality;

- high performance;

- repeatability;

- acceleration of the welding process;

- eliminating downtime, errors and loss of materials;

- reducing staffing costs;

- increasing the safety of the work;

- flexibility and possibility adaptation of the welding robot to the needs of the company.

Modern welding robots Easy Robots

Following the constantly changing market needs and the development of all branches of production, we have developed technologically advanced stations equipped with welding robots with a dedicated learning module. They enable welding of any shapes using different techniques, as well as creating various, even the most complex, welding paths.

We recommend customised robotised workstations and welding cells, which do not require highly qualified and experienced employees to operate. A short training course is all it takes to operate the workstation efficiently and to increase the speed and quality of the welding process!

LEAVE YOUR DETAILS

WE WILL CONTACT YOU