EASY CELL welding cell

Welding cell

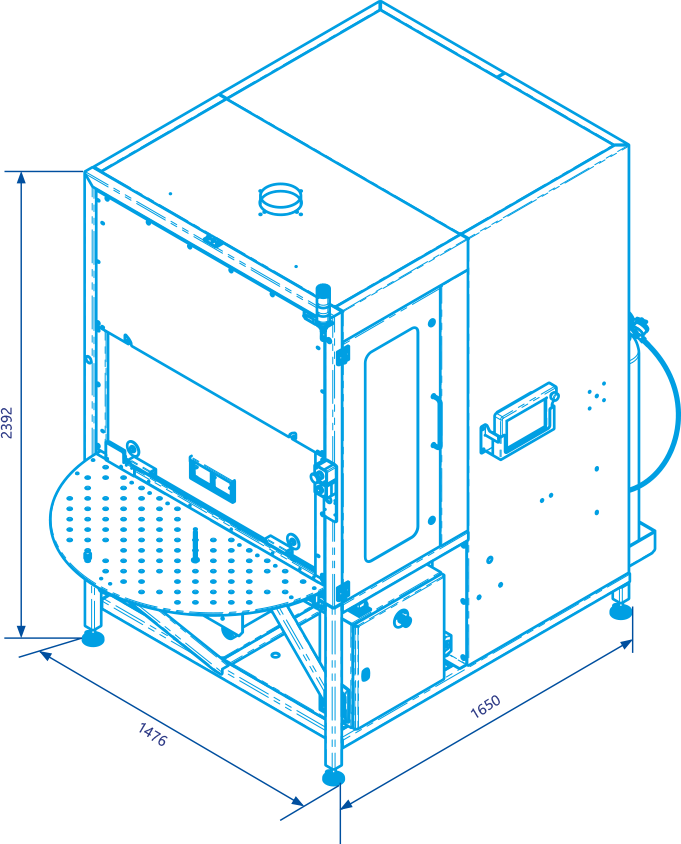

EASY CELL S

Welding cell EASY CELL is an automated welding station with two work areas, where the work of the operator and the welding robot is performed in parallel. The tasks of the former include loading or unloading the processed details, while the welding robot simultaneously performs MIG, MAG or TIG welding on subsequent details.

Not only a cell integrated with a welding robot increases production rate, but also reduces the need for qualified professionals, because it can be operated by a serial operator after appropriate training.

An integral part of the welding cell is an enclosed welding station equipped with a welding robot, a rotary table with a system of holes to facilitate the fixing of instruments, a control cabinet and a mobile operator panel. In order to be able to control the welding process, the cell has been equipped with a viewfinder with UV filter located in the front partition and two windows, located on the sides of the welding station.

Robotic welding as an alternative to manual welding is perfect for medium- and multi-series production as well as multi-assortment production. Its repeatability is so high that the products resulting from the automatic process do not require additional processing.

In the case of our EASY CELL welding cell, the current source, welding torches and accessories in the form of tooling can be configured to the individual customer's requirements.

| Lower costs employee |

|

In this way, we can significantly reduce employment costs.

| Easy programming |

|

The welding robots and integrated welding cells are equipped with touchscreen monitors that allow easy operation of the equipment. A programme wizard, meanwhile, makes it easy to write a ready-made algorithm for a component from scratch.

| Safety and ergonomics at work |  |

| Low costs |  |

| Performance without interruption |  |

| High quality and repeatability |  |

Welding cell from Easy Robots

Our welding cells enable a welding robot and an operator to work simultaneously, by which significantly increases the welding rate. At the same time, they reduce the financial outlay while guaranteeing excellent quality of the manufactured elements due to the high repeatability of the activities carried out. Why is awelding cella great investment?

Above all, it stands out from other solutions. It provides maximum safety (it is a small, sealed workstation), increases ergonomics.

The cell can also be easily moved to another production area. It offers the possibility of MIG, MAG and TIG welding (depending on the equipment selected). The costs of implementing a welding cell are also relatively low.

Even though the presence of an advanced welding cell and the automation of processes occurring in more and more companies decide to do this, a good and experienced welder is necessary to control, supervise and perform more difficult welds. The remaining work can be performed using the described Easy Robots cell.