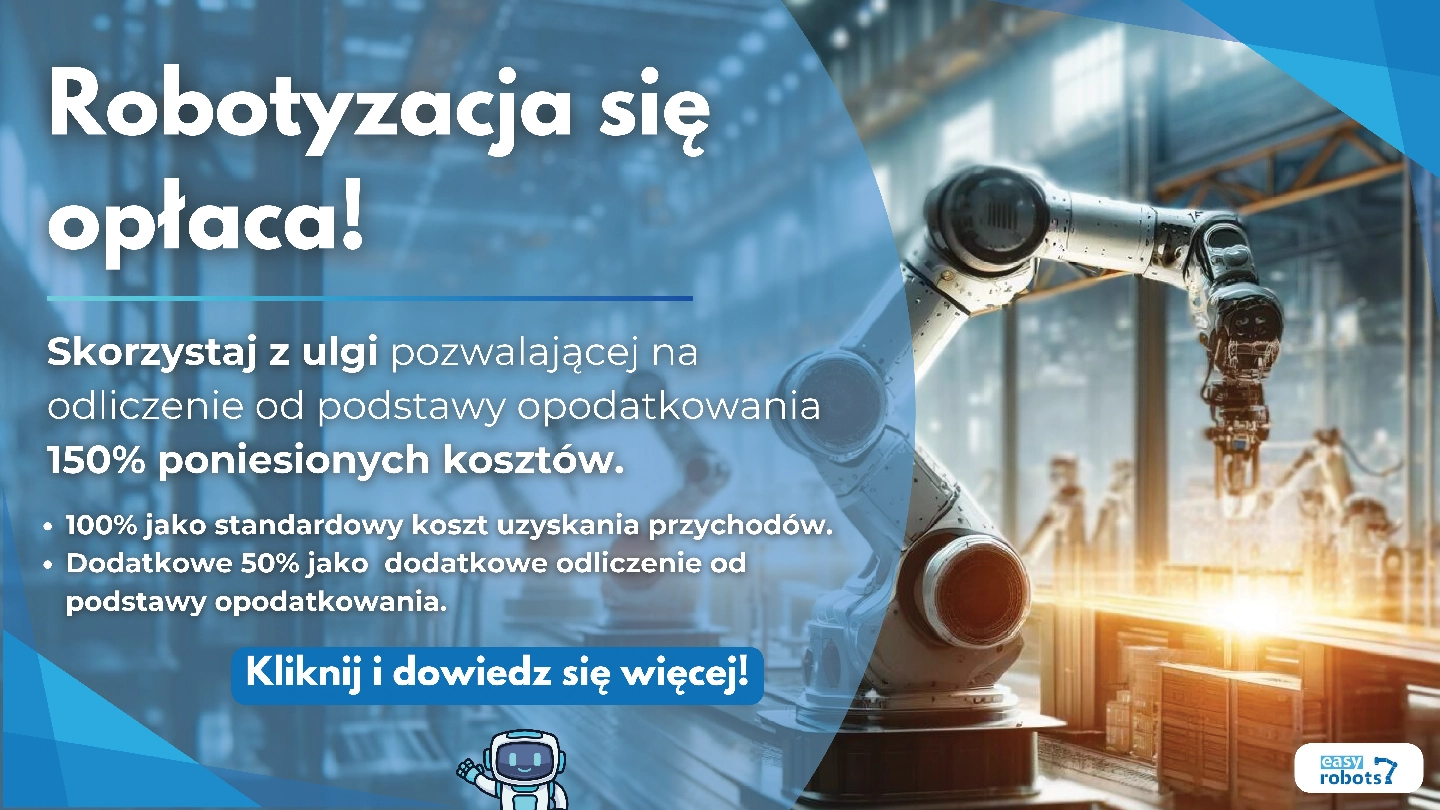

Automated CNC machining cell model BOX CNC

Automated CNC machining cell model BOX CNC

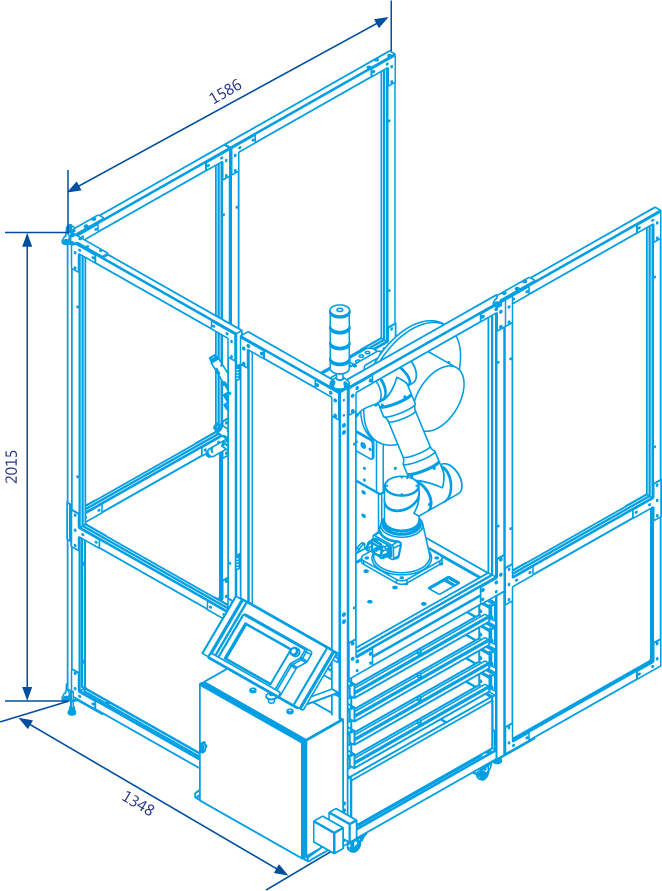

Automated CNC machining cell BOX CNC is a closed module, cooperating with the raw parts and finished products.

The stand eliminates the need for machine monitoring and manual loading of parts, allows you to move employees to other production processes and increases work safety within CNC machines.

BOX CNC is effective support for your production.

Main applications of BOX CNC are: CNC machining centers, lathes, milling machines and hydraulic presses.

| Description |  |

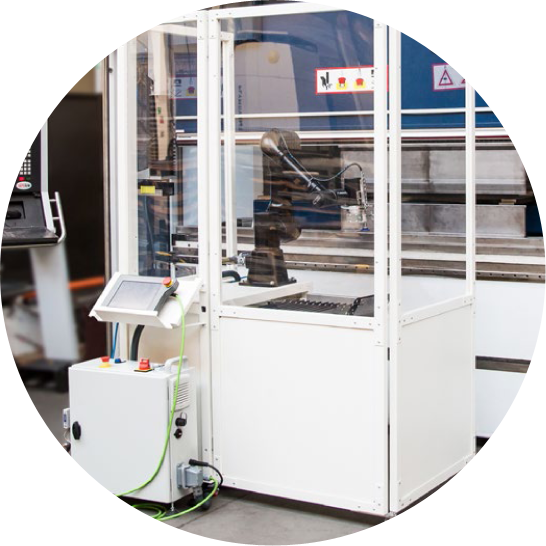

The construction of an automated CNC machining cell consists of a rack with drawers, which is used for storing raw parts to be processed and ready-made components.

The operator places a set of workpieces to be machined in the drawer. Each drawer is universal and can be fitted with different inserts depending on the size of the workpiece. The inserts are interchangeable, so it is possible to replenish the workpieces without having to stop the robot.

The automated CNC machinig cell consists of: 4 drawers with guideways, replaceable drawer inserts, transport wheels with a lock, a casing set, a worktop, bolts for pulling out drawers.

| Advantages |  |

Station mobility and compact structure

Station mobility and compact structure

The wheels of the BOX CNC semi-finished product magazine enable the set to be mobile in order to connect it to the machine tool.

A 6-axis manipulator placed above the drawer magazine minimizes the required work area.  2 in 1: warehouse for raw parts and finished products

2 in 1: warehouse for raw parts and finished products

The drawers can be pulled out on both sides, so they can be refilled without having to stop the robot. Replaceable dedicated inserts allow for quick conversion to other details.  Shorter processing time

Shorter processing time

The universal connector allows the use of grippers for various applications. Simultaneous installation of a 3-jaw and 2-jaw chuck is possible. This solution speeds up the process of receiving and loading parts as much as possible, which translates directly into increased production efficiency.

| EQUIPMENT | FUNCTIONALITIES | BENEFITS |

|---|---|---|

| A SET OF 4 DRAWERSWITH INSERTS | The drawers are covered with a casing and each holds a set of from a dozen to several dozen pieces, depending on the insert design. The design of the BOX CNC ES5 warehouse allows drawers to be pulled out in two directions, which allows the operator to easily load parts and collect finished elements without having to stop and enter the robot's work zone. | CONTINUITY OF WORK AND ELIMINATION OF DOWNTIME Depending on the size of the detail, the warehouse provides material for work for up to several hours |

| EXCHANGEABLE DRAWER INSERTS | Drawer inserts and dividers are used to properly arrange the elements being processed. They can have many designs and contain from a dozen to several dozen elements. | FLEXIBILITY AND DIVERSITY OF PRODUCTION The warehouse is an ideal solution for short-series and special production |

| TRANSPORT WHEELS WITH STOP LOCK | They allow to move the entire set to other machining centers. | MOBILITY Mobility allows for optimal use of machines when we have a multi-stage, short series machining process. |

| CASING | A casing set made of a transparent PMM provides excellent visibility of the robot's working environment, regardless of the machine at which it works. Safety barriers that are part of the security system are equipped with a tower that signals the working states of the cell, and the hinges which allow for the regulation, or opening of a safe zone. | SECURITY Work safety in automated CNC handling. |

| WORKTOP | The worktop is used to mount the robot’s arm. | SAVING SPACE Mounting the arm above the magazine minimizes the required work area |

| BOLT FOR OPENING AND CLOSING OF THE DRAWERS | The bolts allow the robot to pull out and push in the drawers. | AUTOMATION OF PRODUCTION PROCESS |