Automating the bending process in Supron 3

Modernization of the work station at the hydraulic press: the rolling and bending process at Supron 3.

The manufacturing company Supron 3 is a leading manufacturer of fire protection equipment: internal hydrants, protective cabinets, fire hoses and personal fireman’s outfit. Thanks to tradition dating back to 1992 and a great variety of products, it has a high reputation among customers on the domestic market.

SUPRON 3

rue Sadownicza 6, 26-600 RADOM

tél. 48 363 99 66, tél./fax 48 363 21 85

e-mail: supron@supron.pl

L'objectif principal était de moderniser le poste de travail de la presse hydraulique, qui est utilisée dans le processus de laminage et de pliage des détails des armoires, des charnières et d'autres accessoires métalliques.

SOLUTION

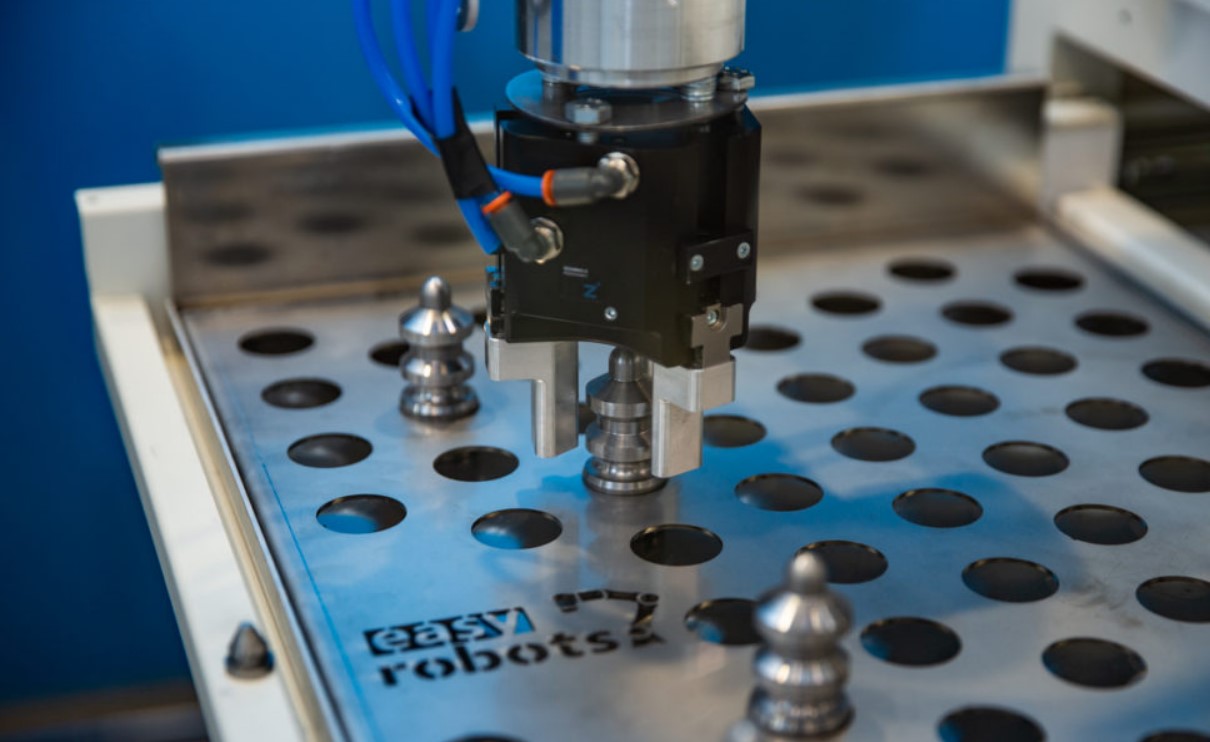

Les programmeurs et concepteurs d'Easy Robots ont analysé les processus de production de Supron 3 et ont recommandé de lancer un projet d'amélioration.

conteneur de pièces

double-sided drawers

profiled trays

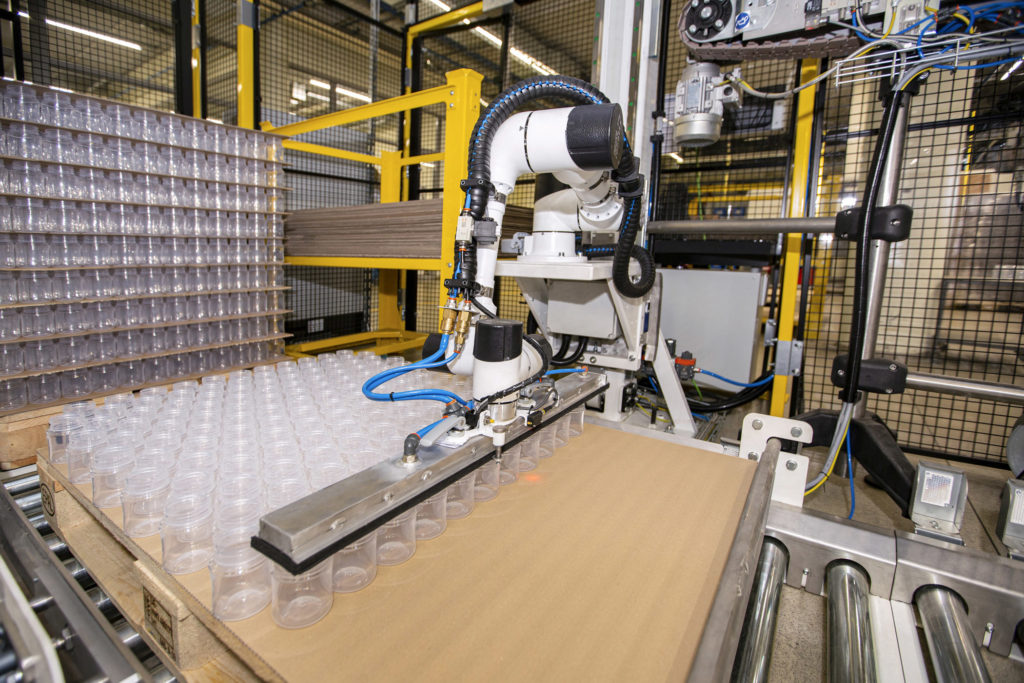

À la suite des travaux, une station a été créée avec un conteneur pour plusieurs centaines de pièces à traiter. Bras robotique ES5 nous avons placé ci-dessus magazine à tiroirs grâce à cela, l'espace de travail requis a été réduit. Les 4 tiroirs du poste, équipés de plateaux profilés remplaçables, permettent aux employés de réapprovisionner rapidement les détails bruts. Ce processus ne nécessite l'arrêt ni du robot ni de la machine. De plus, l'employé n'a pas à superviser le fonctionnement de ces appareils jusqu'à ce qu'il soit nécessaire de remplir à nouveau les plateaux de détails.

2 applications 4 profile designs

processus de laminage et de pliage à un angle de 90 degrés

Le projet comprend deux applications pour 4 modèles de plaques différents. La première application consiste à rouler et la seconde à se plier deux fois à un angle de 90 degrés.

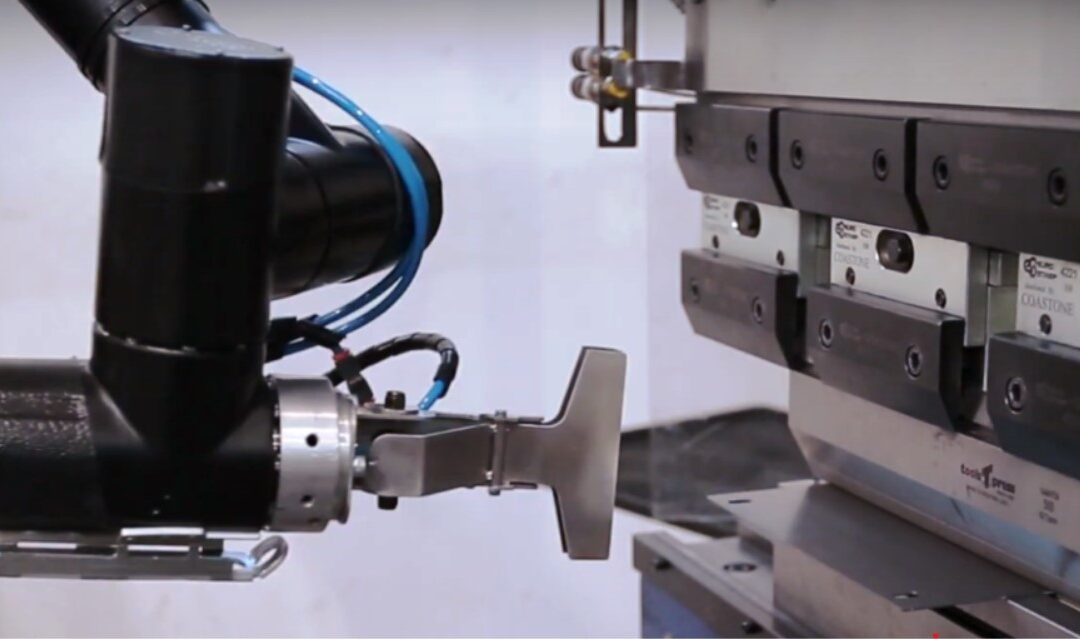

The rolling process

Les plateaux à partir desquels le robot prélève les détails bruts pour le traitement de laminage peuvent être utilisés pour les 4 modèles de plaques réalisés sur la presse. Le manipulateur ES5 écarte les tiroirs et récupère la pièce de sortie du plateau, puis la place sur la matrice de la presse plieuse. The rolling process il comporte plusieurs étapes. Le bras robotique place le détail sur différentes étapes de la matrice jusqu'à l'obtention de l'élément fini, qui est ensuite automatiquement déposé sur le convoyeur.

The bending process

Dans le processus de pliage A l'angle droit Les feuilles déjà roulées sont extraites des tiroirs puis acheminées vers la presse plieuse. Le pliage comprend deux procédures, après lesquelles le robot récupère la pièce finie de la machine et la place sur le convoyeur.

RESULTS

INCREASE IN SAFETY

Le pliage robotisé a modifié le modèle de travail actuel. L'automatisation permet aux employés de se concentrer sur des tâches importantes plutôt que sur des activités de routine, qui peuvent être sujettes à des erreurs, voire dangereuses, à mesure que le quart de travail progresse et que l'opérateur devient plus fatigué.

ONGOING WORK

Non seulement le temps d'exécution d'un seul processus a été réduit, mais les plateaux de détails utilisés dans le magasin à tiroirs ont également assuré la continuité du travail.

MOINS DE 35 SECONDES POUR LE PROCESSUS COMPLET

Même si l'augmentation de la productivité n'était pas une priorité dans ce projet, il a également été possible d'augmenter cet indicateur. La norme moyenne résultante pour un employé dans le processus de laminage était jusqu'à présent de 45 secondes pour un processus complet, du détail brut à la finition. Cela prend actuellement moins de 35 secondes au robot.