Cobot or no cobot? That is the question!

FEBRUARY 18, 2019

Collaboration between humans and robots has recently become a mega trend, but will a cobot work in every company?

In times when the demand for products changes almost at the speed of light, entrepreneurs must be more open to market needs, which directly leads to greater automation, which does not come at the expense of production flexibility.

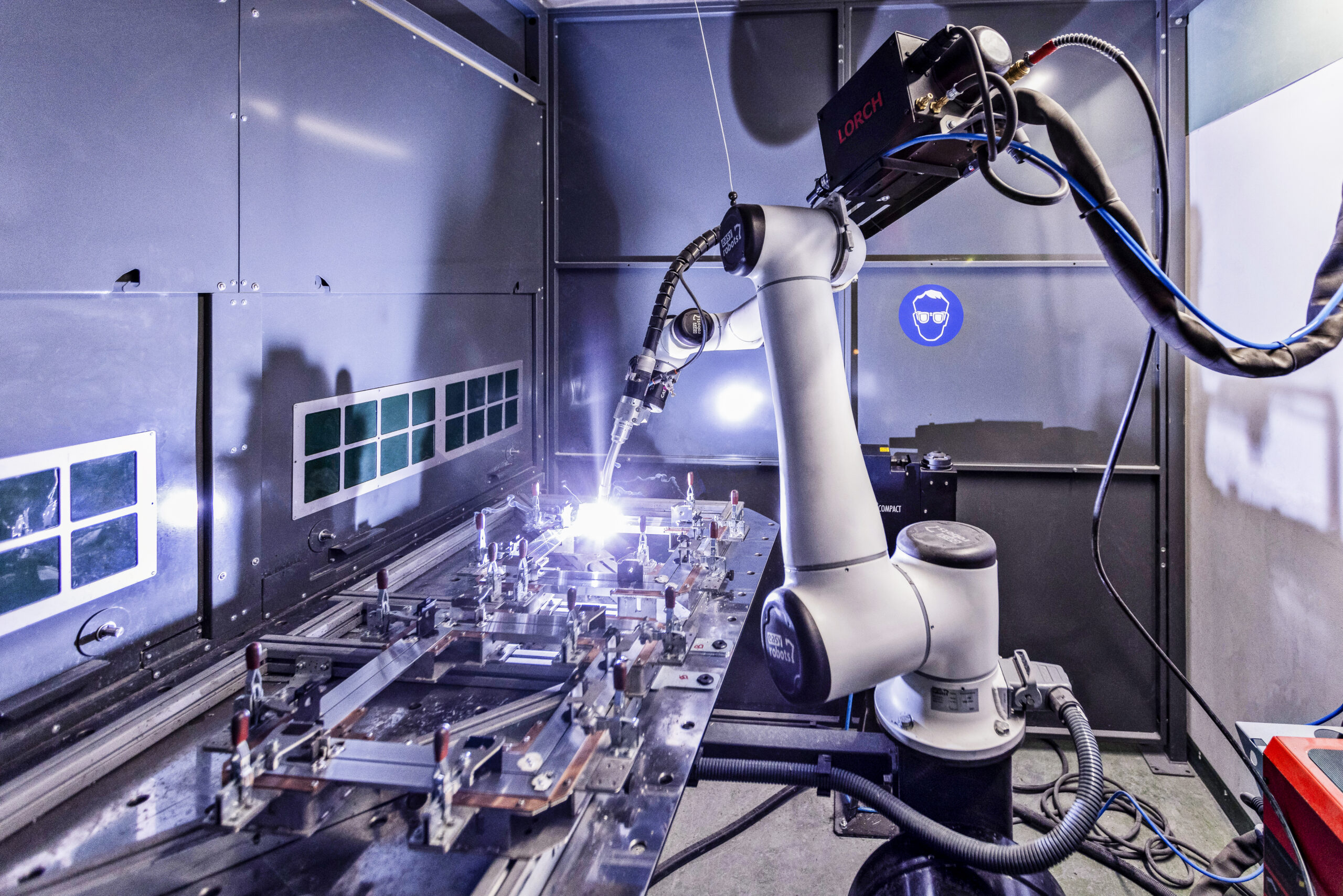

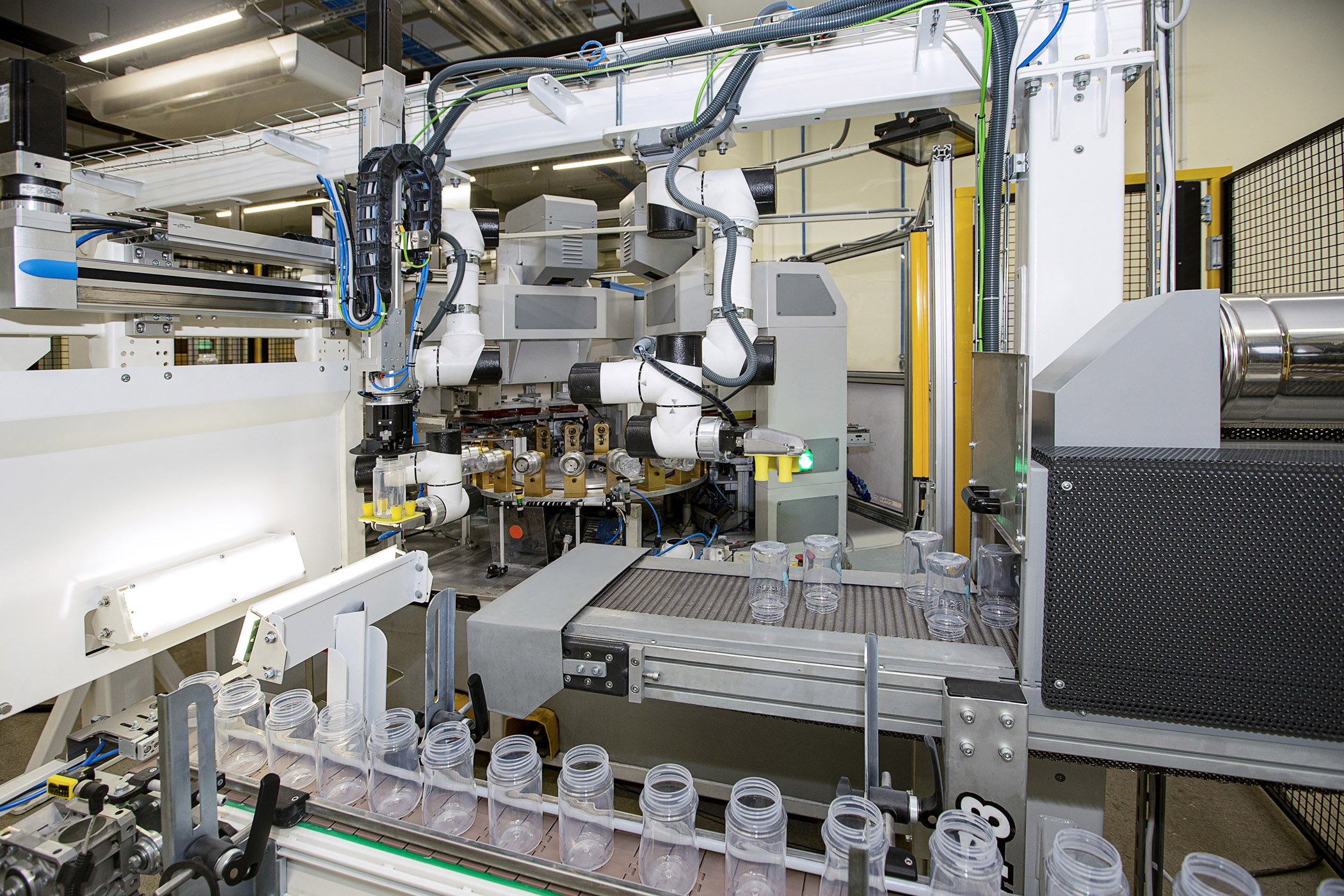

The use of robots on the production line is intended to free people from performing non-ergonomic, monotonous tasks, such as lifting and positioning loads, or working in harmful conditions during welding or in a paint shop. Robots are also used to modernize industrial facilities to maximize production capacity.

Robot, cobot, collaborative robot?

According to the website Wikipedia, the word robot: originally referred to living beings - an artificially produced, simplified version of a human intended for hard work, now the word primarily means mechanical devices. The word cobot is a combination of words collaborative and robot, because the essence of collaborative robots is safe machine-human interaction.

Collaborative robots, like any robot, can work 24 hours a day. They significantly save working space compared to traditional manipulator models, and there is no need to use protective barriers. Structurally, rounded shapes are used, and advanced systems such as defining safety zones, collision detection and collision force control are intended to ensure safe operation.

Is price the only thing that matters?

Before purchasing a cobot, you should first consider in what work areas it is to be used, e.g. machine operation, inspection, assembly, and whether it is economically justified to introduce a collaborative model into production.

If we want to calculate the rate of return on investment (ROI), we should take into account not only the cost of integration and adjustment of the line, including the time needed for implementation, but also the cost of the cooperating gripper, which may constitute the lion's share of the entire investment. It may turn out that we will invest in collaborative robots, but only a risk assessment of the entire installation will determine whether they can be used in this capacity.

Purchasing decision-makers also take into account the possibility of controlling other devices that interact with the robot, i.e. software, its interface and expenses related to updating or adding new functionalities.

The flexibility of a given model, i.e. adaptability to various production cells, is of great importance to maintain the cyclical nature of production, but if time is important...

If the most important selection criterion is to increase the efficiency of the technological line while maintaining high quality, traditional industrial robots that can operate at full speed will be a better solution. However, they do not have to be huge, heavy machines - as was the case recently - complicated to use and dedicated to one specific task. Currently, light and small, universal manipulators open up many new perspectives.

So cobot or no cobot?

Technologies are changing the way enterprises operate, and the scope of modernization depends on the goals to be achieved. To meet the individual needs of customers, manufacturers ensure the multifunctionality of the manipulators, intuitive programming and easy adaptation to various applications. An example is our key product – a robot ES5.

All factors important when choosing collaborative robots should be carefully analyzed and choose the solutions that will be the most beneficial for our company in the long run.