Robotization of workplaces is the future in many industries!

MAY 22, 2020

Until recently, we associated robots only with science fiction films, in which the idea of them is far from the reality we face in the 21st century. Contrary to appearances, they have not taken over the world and replaced humans - on the contrary, they can serve him perfectly by increasing the efficiency of everyday activities. Modern solutions make it possible robotization of workplaces and They are perfect for companies operating in various industries. Which ones and is it really worth considering "employing" a robot? Be sure to read it!

Robotization of workplaces, or what exactly?

However, before we move on to the applications of robots, it is worth first finding out what they really are. From the entrepreneur's point of view, a robot is a device with a task support people in routine, repetitive and burdensome activities for the employee. And that also in the most difficult conditions that could be dangerous for a person employed in the company. Modern machines cooperate with humans and, thanks to appropriate programming, are able to perform specific activities for them.

Robotization of workstations it is therefore an introduction to the production process of robots and other accompanying devices. In this way, it is possible to automate it and, as a result, increasing the efficiency and repeatability of work, increasing the precision of activities and optimizing costs. That is, everything that an entrepreneur cares about - regardless of the field he specializes in.

Good to know! The concept of "robot" is extremely broad and we call various types of machines this way every day. Industrial manipulators are particularly popular in the industrial sector, most often in the form of a mechanical arm that is able to perform various tasks, including those that are dangerous to humans.

Industries where robots will prove useful

Manipulators are devices that can be easily programmed and thus adapted to specific needs and tasks. They can work 24 hours a day, perform a wide range of activities and work in the most difficult work environments – that's why they are becoming more and more popular. Let's find out what purposes they can be used for and in what industries robotization of workplaces is particularly advantageous.

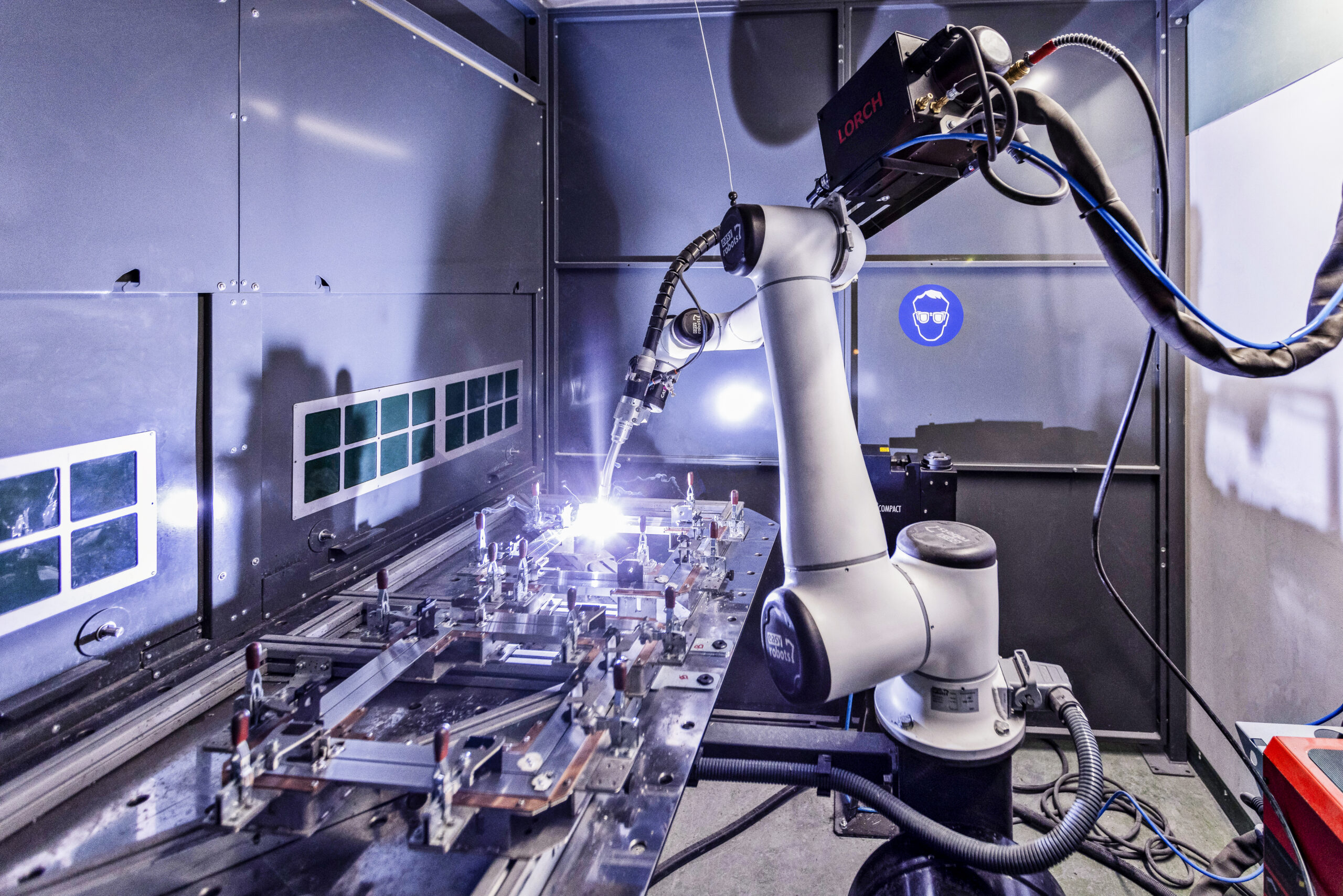

Metal industry

The metal industry requires high precision of operations, and some work may be too difficult or monotonous for humans. Therefore, robots play an important role here - they help in joining metals, such as welding or welding. The use of manipulators to operate CNC machines is particularly popular among entrepreneurs. Thanks to this, it is possible to significantly increase the efficiency of technological processes in plants dealing with, among others, turning, milling, bending on press brakes or stamping lines.

Electronics

Reliable grippers are particularly appreciated in the electronics industry, which - thanks to the use of very advanced technology - are able to cope with the production of various types of equipment, such as processors, where we are dealing with delicate silicon structures. Specialized force and torque sensors enable robots to lift, move or assemble even the smallest elements. While maintaining the highest precision and repeatability of work.

Automotive

Robots have also been used for years in welding and welding car parts (e.g. bodywork), attaching various types of clamps, screwing in screws, and even advanced anti-corrosion protection processes, including painting. In this way, they play a very important role in the automotive industry, and the largest brands on the market use them. In today's world, it is difficult to imagine a modern car factory in which industrial manipulators do not play a key role on production lines.

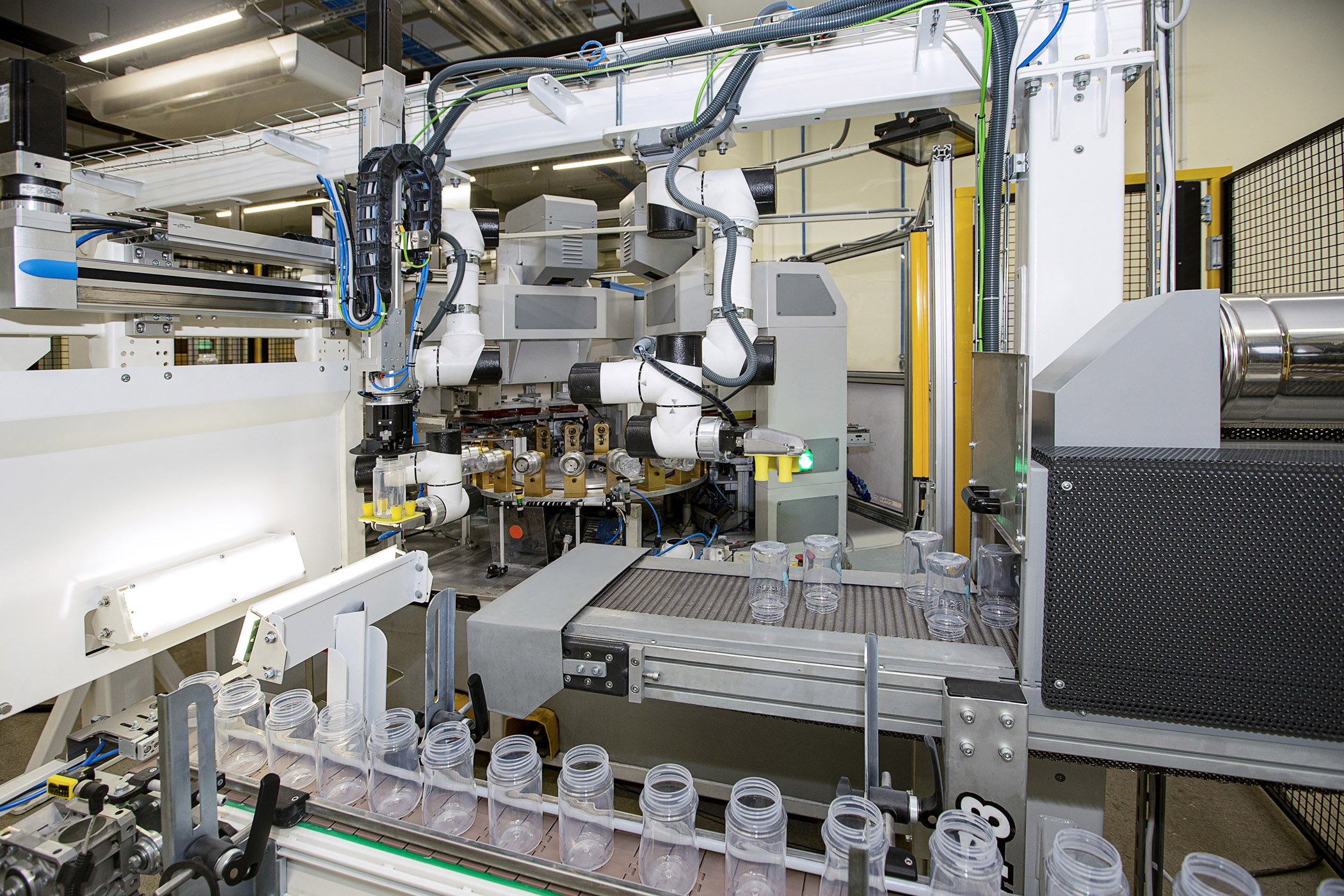

Plastics

As in the case of the metal industry, robots can support production processes that use materials such as PVC, PP, PU or ABS. Here, too, they can easily operate CNC machines, including: injection molding machines, and because they work in a repeatable and continuous manner, they significantly contribute to increasing production efficiency.

Furniture industry

It will benefit from robotization also the furniture industry, where robots can perform many activities - including gluing furniture, applying varnish coatings or moving elements. We are talking about activities that are tedious and difficult for humans to perform, especially in the perspective of long hours of work.

Pharmaceutical industry

Robots will prove useful wherever surgical precision is necessary, including in the pharmaceutical industry. They can be used not only to automate the drug production process, but also to transfer drugs between individual control stations or close vials and bottles.

In this case, robots also play an important role from the point of view of the safety and quality of medicines, which must be at the highest level.

Food industry

Robotization of workstations also takes place in the food industry - robots will prove useful on production lines, enabling packaging, palletizing and sorting of various types of products.

Other

The industries mentioned are just the tip of the iceberg. Robotization of workstations it also affects other industries where the work performed is difficult and repetitive, and the key to production success is the highest precision. We are talking about the automotive industry, chemical industry, medicine, quality control and many others.

A huge advantage of currently produced robots is that they can be adapted to various types of activities. Therefore, regardless of the industry in which the company operates, its owner may have the opportunity to invest in a personalized solution, tailored to individual needs and business goals.

Robotization of workstations – the most important benefits

The most important benefits it brings robotization of workplaces, we include:

- supporting employees in difficult, tedious and repetitive activities;

- increasing the efficiency of production processes;

- ability to perform work with the highest possible precision and full repeatability;

- ability to use the robot 24 hours a day;

- ease of programming and operating robots – using intuitive touch panels;

- universality of use - robots can be used in every industry;

- possibility of using innovative technological solutions.

Robotization of workstations Today, it is not only an option, but also a necessity in many industries. Thanks to it, the entrepreneur will be able to compete effectively with the most modern companies on the market and gain an advantage over those that still do not use the potential of robots.

Of course, the key to success is the selection of appropriate solutions that will be dedicated to a specific industry and using the offer of a reputable manufacturer. At EASY ROBOTS, we supply entrepreneurs with the most technologically advanced robots and grippers. We provide welding stations, CNC machining centers and palletizing stations, as well as multi-axis systems. Our robots can also be used to build production cells, which will significantly improve the work of any enterprise.

A huge advantage of our company is the experience in the production automation industry gained in entities closely related to Easy Robots, as well as the undoubted willingness to take up new challenges in the industry of automation and robotization of production processes!