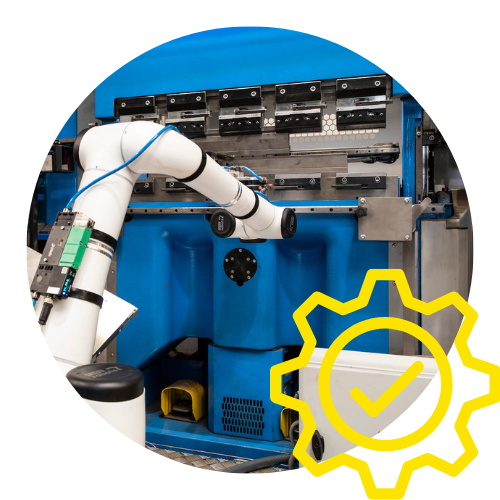

Robotization of press handling

Robotization of the bending process on presses

Robotization of the bending process on presses is an extremely important step in the pursuit of increasing efficiency and precision in the metal industry. Thanks to the use of modern robots and automation systems, we can significantly improve production, shortening time and increasing efficiency.

The bending process on press brakes is an operation thatrequires precise andrepeatable movements to obtain the desired shape and accuracy. Traditional methods, based on manual manipulation of sheet metal, are time-consuming, error-prone and limited by the capabilities of operators. That's why more and more manufacturers decide to automate this process.

Robotization of sheet metal bending - what to pay attention to for it to be effective?

Synchronization of the movements of the press and the operating robot is extremely important. By precisely matching the movement axis of the robot and the press, we can achieve significant acceleration of the bending process and increase the efficiency of the entire production line.

For this reason, an extremely useful aspect of bending robotization is the use of a dedicated module for operating the station by the operator. This module ensures simple operation of the station, allowing the operator to easily program and control the bending process. The additional module facilitates programming, speeding up work and minimizing the possibility of errors.

An important aspect is also the design of the robot's gripper, which enables not only the transfer and positioning of metal sheets of various dimensions and weight, but also quick and effective switching of the gripper if it is necessary to change parameters processed sheet metal. Thanks to this, even with large differences in dimensions or parameters, we can maintain the smooth operation of the workstation. The introduction of robotization of sheet metal bending allows for optimization of the process andincrease in production efficiency.

Do you need more information about our robotic sheet metal bending machines? Download folder!

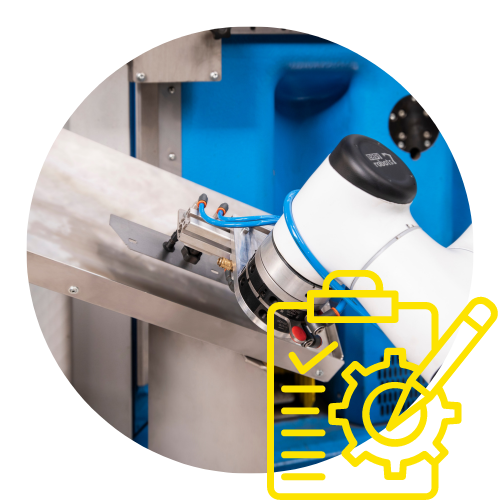

Get to know EScontrol software with a dedicated bending module

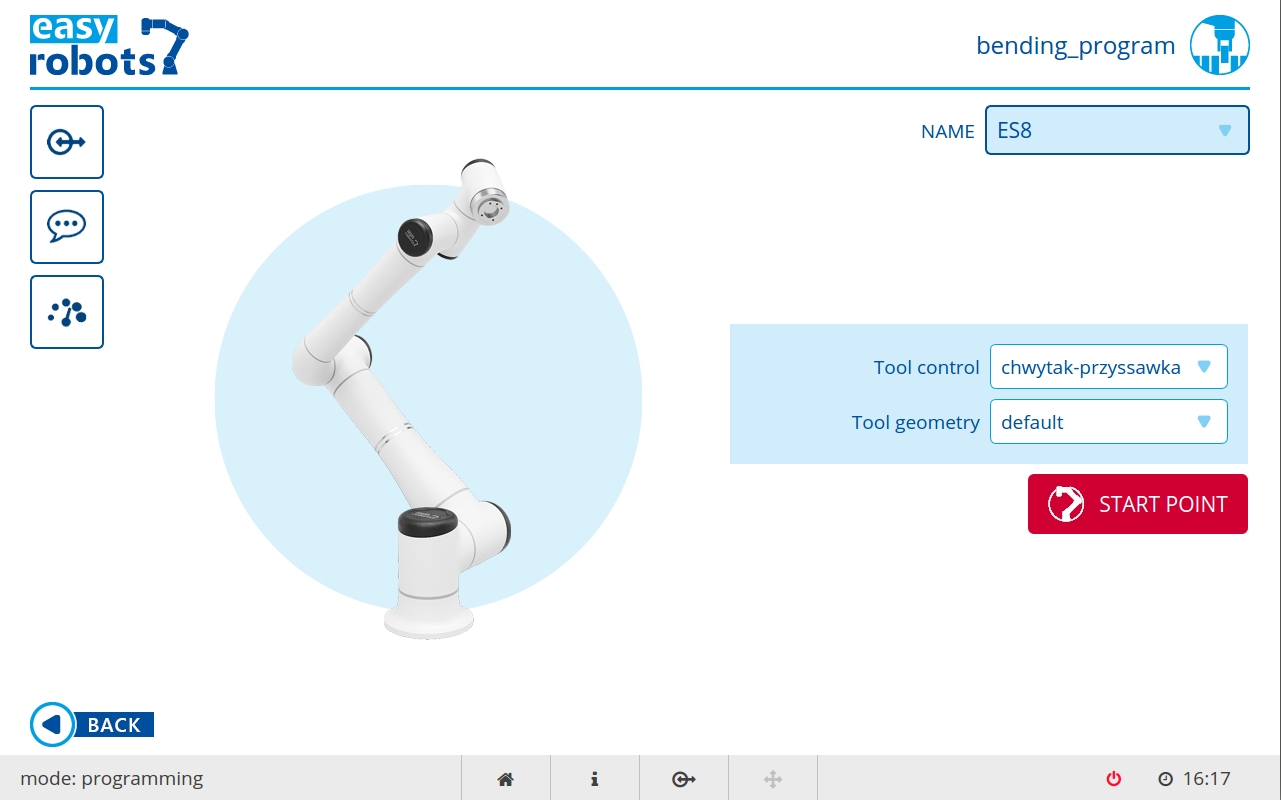

EScontrol is an innovative software that has been equipped among others ina dedicated module for bending sheet metal. It offers a number of benefits that contribute to the effective and precise programming of the bending process.

Makes the programming process much easier and faster. With integrated tools and features, users can easily create and modify bending programs, saving time and effort.

Has an intuitive interface on a touch screen that allows operators to quickly and conveniently programming and control of the bending process. Thanks to this, they can easily adjust the settings and parameters to their individual needs..

Enables constant control of parameters. Operators have full control over bending parameters such as angle, force and speed. Thanks to this, they canprecisely adjust the settings to the requirements of a specific task and achieve excellent bending results.

Enables remote diagnosis of the robot's operation. Operators can monitor and analyze robot performance from anywhere via remote access. This enables to quickly identify possible problems andresolve failures effectively, which helps to minimize production downtime.

What the robotic press bending system with Easy Robots industrial robots is all about

Robotic workpiece bending is an automated process in which an industrial robot performs bending operations on press brakes. The process consists of several main steps:

| ROBOT PROGRAMMING |  |

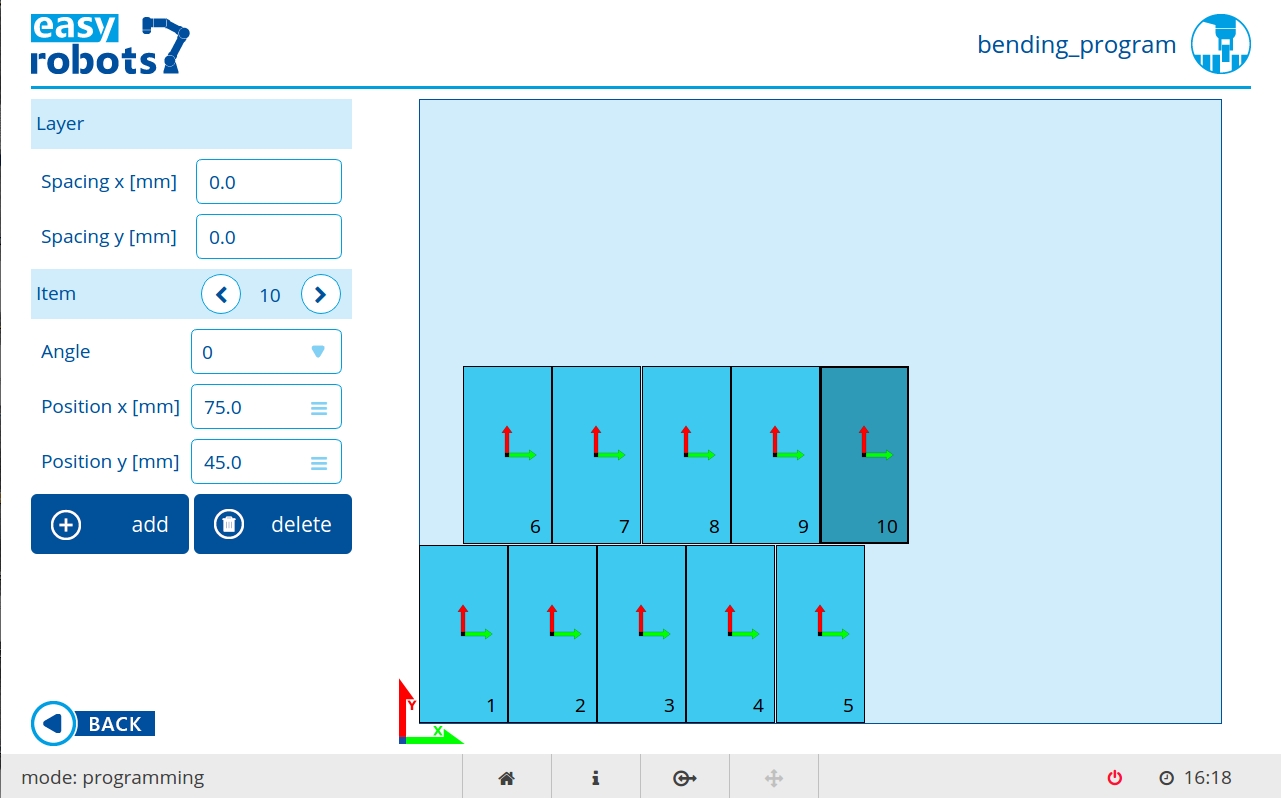

At the beginning, it is necessary to program the robotto perform appropriate bending operations. Programming is done using a dedicated module in the EScontrol software, which allows you to define the movement trajectory and bending parameters.

| MATERIAL PREPARATION |  |

The operator places the details on thepositioning tableor in a special loading area. These may be, for example, sheets or metal bars.

| WORKPIECE POSITIONING |  |

The robot precisely positions the details on a specially prepared tool to ensure accurate and repeatable introduction of the details into the press brake. Thanks to this, each element is bent in exactly the same way.

| RETAIL BENDING |  |

A program-controlled robot performs bending operations on the press. It uses a specially prepared tool, such as a gripper, which holds and processes details in accordance with the established movement trajectory and bending force. The robot ensures precision and repeatability in the bending process.

| PUTTING DETAIL AWAY |  |

After performing the operation, the robot places the bent detail at the target location, which may be a conveyor, pallet or other dedicated collective packaging. The robot precisely positions the detail in this place, ensuring accurate placement and minimizing the risk of damaging the detail. Thanks to this, after bending, the detail is ready for further processing or transport.

| QUALITY CONTROL |  |

After the bending operation, the details can be subjected to quality control to check the accuracy of dimensions and quality of workmanship. This may include geometric measurement of details using measuring devices or verification using vision systems.</span

Benefits of automating press handling

The use of robots in the bending process on presses brings tangible benefits to manufacturing companies, enabling greater efficiency and precision and quality in the production of bent metal elements. Here are some of the main ones:

- Increased efficiency and speed

Industrial robots are much faster than human service. Thanks to this, you can achieve higher production in a shorter time, which translates into an increase in the efficiency of the entire bending process. - Excellent repeatability

Robots are programmed to precisely perform bending operations . Thanks to this, they ensure repeatability at the highest level, eliminating human errors and achieving excellent quality of bent details. - More flexibility

Industrial robots can handle a variety of sizes and shapes elements, which gives greater possibilities in the production of various products. - Employee safety

Bending on presses can be dangerous for operators , especially when working with large and heavy elements. Robotization of this process minimizes the risk of accidents and injuries because employees do not have to directly manipulate materials. - Optimal use of raw materials

Thanks to precise robot control, consumption can be optimized raw materials. Robots minimize waste and reduce the amount of material needed for production, which translates into savings and greater efficiency. - Long-term profitability

Although investing in robotics may require an initial outlay financial, brings long-term economic benefits. Higher efficiency, savings on raw materials and minimization of labor costs translate into the long-term profitability of the bending process.

Which bending presses can an industrial robot work with?

ES series industrial robots can work with all types of bending machines available on the market. Depending on the type of production, it can be programmed to handle:

1. Press brakes

These are the most popular type of bending machines used for bending flat metal sheets. The sheet metal is placed between the bending machine's tools and then bent along the edges to create the desired shape.

2. Roller presses

They are mainly used for bending pipes, profiles and rods . Roller benders consist of three or more rollers that rotate the material while bending it into the desired shape.

3. Wire presses

Are specifically designed for bending wire or bars with smaller diameters. They are used in the furniture industry, electronics, production of springs and reinforcement elements.

4. CNC presses

Computer numerical control (CNC) bending machines are advanced machines that allow you to programmatically control the bending process. Thanks to this, precise bending of complex shapes can be achieved.

5. Hydraulic Press

Benders use hydraulic force to bend materials. They are often used in heavy industry where higher bending forces are required.

6. Electromechanical presses

Use electric motors to drive the bending movement. They are more energy-efficient and precise compared to hydraulic bending machines.

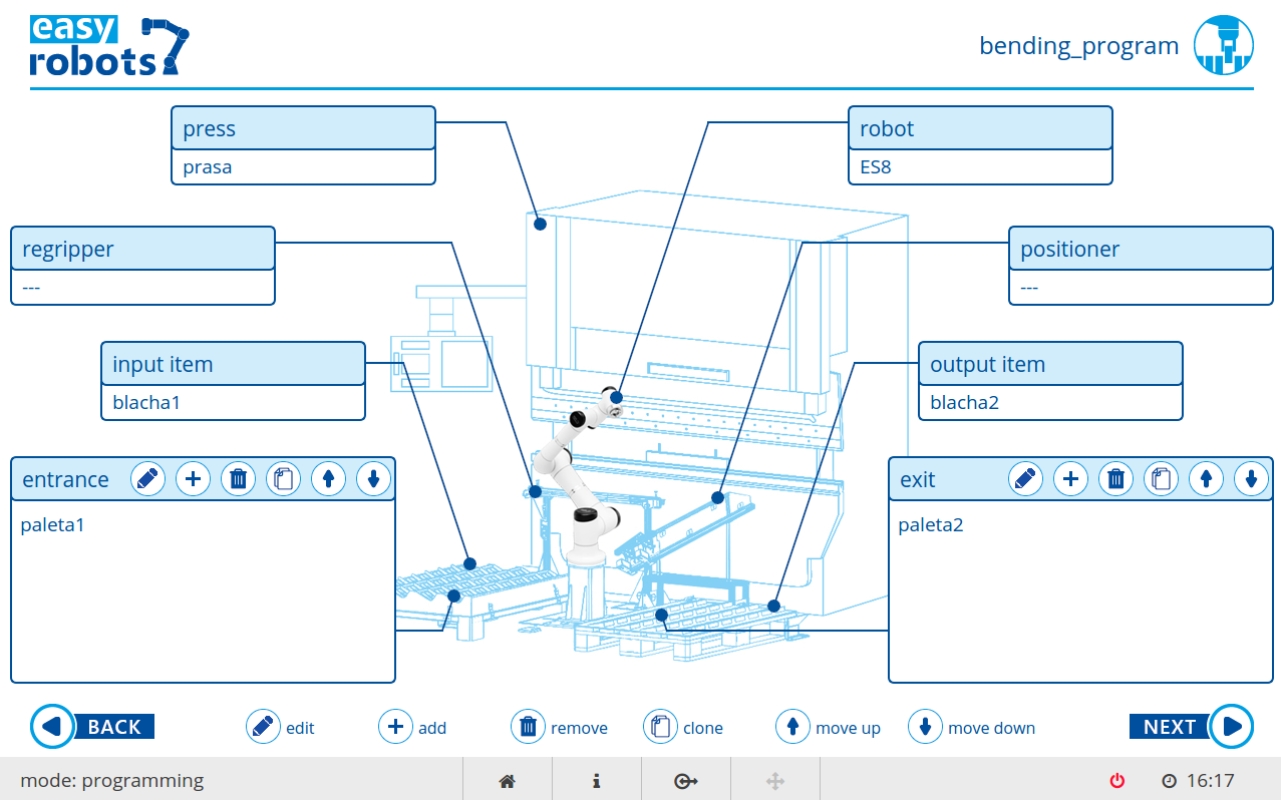

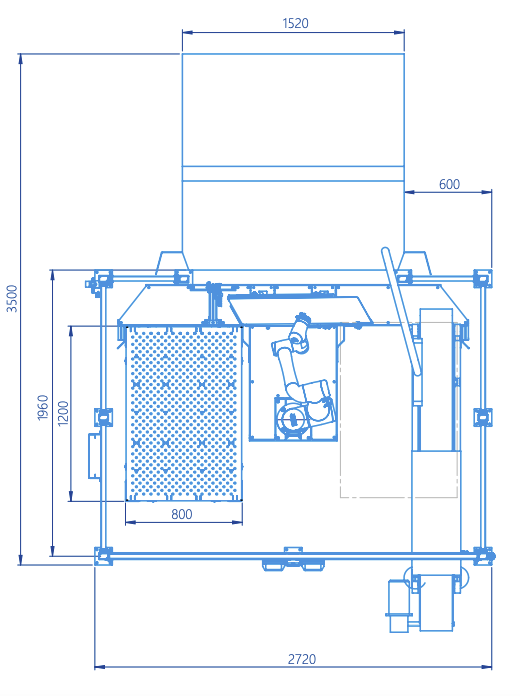

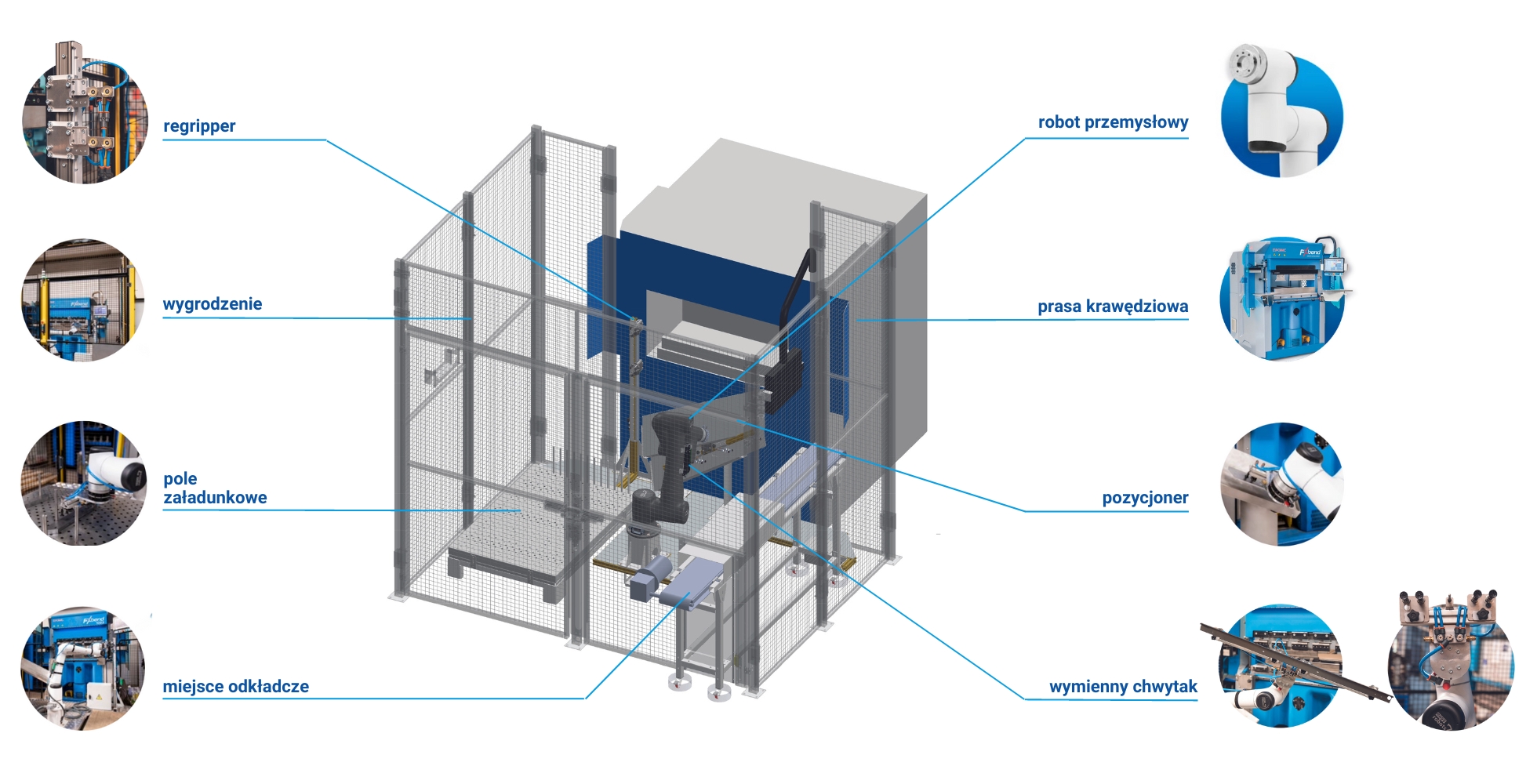

Robotic bending station with a press brake

Robotic bending process

At the beginning of the process there is a perforated input pallet, which allows different types of details to be supplied to the robot. The robot arm uses a gripper to catch the element to be bent. To ensure the repeatability of each cycle, before being fed to the press, each detail is placed on a positioner. The positioner ensures clear positioning and gripping of the detail, which is crucial for the correct execution of subsequent bends in the press.

After downloading from the positioner, the detail is fed to the press. The robot performs the necessary interceptions to deliver the element and perform subsequent bending. After the process is completed, the robot transfers the finished detail to the receiving pallet.

In order to ensure work safety, the integration of the press communication system with robot. In practice, this means the exchange of signals between the press and the robot, which enabled the synchronization of the operation of both devices. Thanks to this, ES8 can respond appropriately to signals from the press and adjust its actions depending on its operating status.

Additionally, the stand is equipped with sound and light signals. After the receiving pallet is full or after all the details from the input pallet have been processed, the operator is informed about this by sound and light signals. This is important for process efficiency, enabling quick response and pallet replacement. Additionally, there is an option to replace the receiving pallet with a conveyor transporting finished elements outside the fenced area. Such a conveyor allows you to continue work in the future without having to interrupt the process when the receiving pallet is full.

To sum up, the implemented robotic station for operating the press brake allowed for the automation of the process, which contributed to increased productivity and production efficiency. Robot ES8 is responsible for collecting semi-finished products from the input pallet, delivering them to the press, collecting finished parts and placing them on receiving pallets. Thanks to a separate work area and an integrated security, sound and light system, the work process is safe and effective.

Robotic bending - why should you bet on it?

| Productivity and efficiency |  |

Robotization of presses contributes to a significant increase in production efficiency and effectiveness. The robots are able to work continuously, demonstrating high precision and repeatability. They eliminate errors resulting from the human factor and minimize time and costs associated with bending operations. Thanks to this, production can be carried out faster and more efficiently.

| Employee safety |  |

Presers are devices that may or may not be dangerous to operators. Thanks to robotization, workers are relieved of the burden of manually manipulating parts and are protected against possible injuries. The robots are equipped with safety systems that minimize the risk of accidents and create a safe working environment.

| Multitasking and flexibility |  |

| Precision and quality |  |

Industrial robots are known for their excellent precision and repeatability. Thanks to this, the bending of details is performed with extreme accuracy, ensuring high quality of the products. Elimination of human errors and precise positioning of details translate into excellent results and customer satisfaction.

info@easyrobots.eu

+48 608 697 888

You can also take advantage of the knowledge of our experienced engineers and make an appointment for a free consultation!

WE WILL ADVISE YOU!